Successful Design and Prototype Patient Specific Bon and Spinal Implants Development at IIEST

A biomechanics team of IIEST Shibpur has successfully developed a method to design optimal orthopedic implants which take into account the bone condition of individual patients.

The team extensively used CT and MRI images followed by modeling to extract the information related to density of bone. It is well known that the increasing older population of the country is suffering from an increase in age-related musculoskeletal degeneration that causes tremendous pain. However, most present day the implant materials are generally stiffer than bone, there is difference in strains between them on physiological load bearing conditions producing dissimilar interfacial stress distribution resulting in zonal stress shielding. Thus the group has performed studies with aim to reduce the effective stiffness of the implant material by incorporation of internal cavity in one approach.

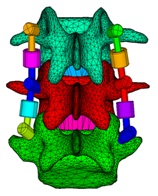

The implants designed by this method are expected to reduce the rate of failure. Similarly, spine injury is mostly indicated at the lumbar spine (L3−L5) and corresponding inter-vertebral disks. Finite element analysis (FEA) is now one of the most efficient and accepted tools used to simulate these pathological conditions in computer-assisted design (CAD) models. Three different loads were applied at the top surface of the L3 vertebra, while the lower surface of the L5 vertebra remained fixed. Models of implants using stainless steel and titanium alloy (Ti6Al4V) pedicle screws and rods with three different diameters (4, 5, and 6 mm) were inserted into the spine models. Results of their analyses indicate that the 6-mm pedicle screw diameter is optimal for most cases.

These projects have been funded by several government agencies and the present prototypes are manufactured in collaboration with CGCRI and IISc Bangalore.